LEXY

LEXY

LEXY, Lake Electric was founded in December 1994, with the English name Kingclean (meaning "King of Cleaning"). It is a company with high-speed motors as its core technology and specializes in green smart small household appliances such as home cleaning, air purification, water purification, and kitchen appliances. , gardening tool products and core supporting parts as its main business, and a home appliance enterprise with its own brand, ODM global export and core supporting parts business as its business model. Lake has strategic cooperation with many of the world's top 500 companies. Its output value in 2021 reached 7.9457 billion yuan, and its products are exported to more than 100 countries and regions.

The Challenge!

The main LEXY's products are electrical appliances, such as vacuum cleaners, air purifiers, water filters, or other equipment. It is certain that the manufacturing processes are significantly different, resulting in different Bill of Materials (BOM) for production. Therefore, LEXY Company must have system to record and remember all production procedures as standards. In particular, when doing Original Design Manufacturing (ODM), customers have a high level of trust in the company. Therefore, customer-specific formulas must be accurate and follow the specified standards in every aspect. The problem with the previous system prevented LEXY Company from working efficiently as follows:

- System cannot connect to machinery to monitor data, and cannot track work processes in real-time or control them comprehensively.

- Problems with managing employees and evaluating complex Key Performance Indicators (KPIs).

- Cannot control and monitor operations in multiple factories.

- System cannot store and remember a large number of production recipe details.

- No alert signals when machinery encounters issues, and the inspection process takes time for consideration.

Argo MES Module

-

Connected current ERP with Argo MES and SCADA to link data together

-

Add customized application to match with working process

After using Argo MES

After finished installation the Argo MES system in 6 factories, the production processes have become much more efficient as follows:

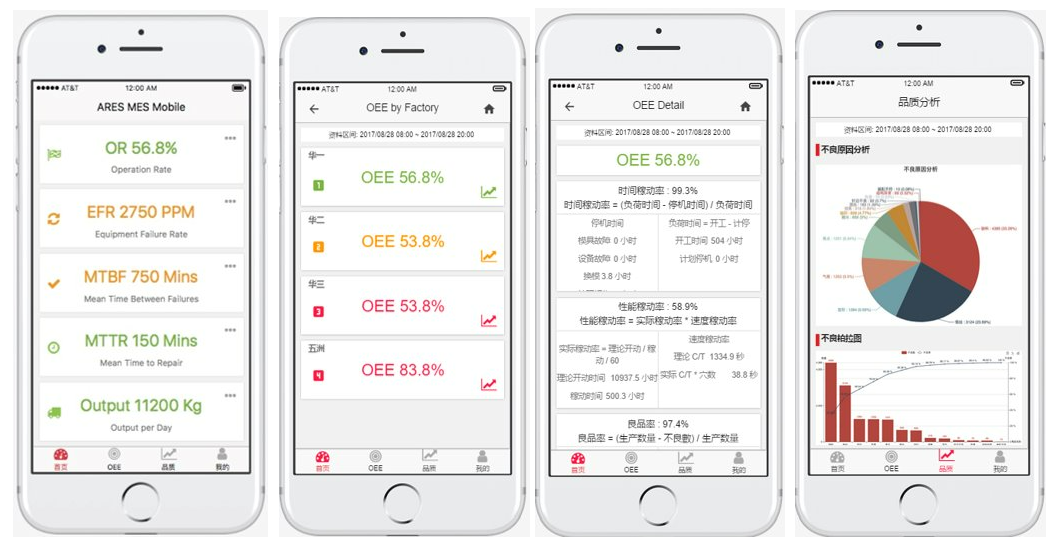

- Argo MES system allows real-time tracking of Work Orders (WO) and Work in Progress (WIP), enabling supervisors and management to monitor work and control employees immediately.

- Additional special working applications are implemented to make employees' work more convenient and to monitor employee KPIs.

- Argo MES system provides comprehensive data to the ERP system for efficient cost calculation and profit-loss analysis.

- All production process data is compiled into the Product Resume for certification and backward traceability, including production lot, component details, machinery serial numbers, and more.

- Data on Overall Equipment Effectiveness (OEE) is obtained from SCADA and recorded in Argo MES system, accessible through the Product Resume.

- Accurate QC data can also be used for online SPC (Statistical Process Control).

- Quality control (QC) of products can be check real-time by checking the details and entering data into Argo MES system immediately.

- Argo MES system's notification feature can also receive temperature data. If the machinery operates at temperatures that are too high or too low, it can issue alerts as well.

- Employees are required to scan the correct raw materials according to the production order before enter the production machinery. If there is any mistake, the system will immediately notify (as the machinery and the system are interconnected).

- Argo MES system records the working time of all machinery to alert employees when it's time for maintenance checks.

- Argo MES system seamlessly connects to machinery and provides comprehensive production data.

Contact us for more information : 0633253640 or 02-6863000 ext. 3042

Email: support@aresth.co.th